| Computer Modeling in Engineering & Sciences |  |

DOI: 10.32604/cmes.2021.013810

ARTICLE

Exact Run Length Evaluation on a Two-Sided Modified Exponentially Weighted Moving Average Chart for Monitoring Process Mean

Department of Applied Statistics, King Mongkut’s University of Technology North Bangkok, Bangkok, 10800, Thailand

*Corresponding Author: Yupaporn Areepong. Email: yupaporn.a@sci.kmutnb.ac.th

Received: 22 August 2020; Accepted: 09 December 2020

Abstract: A modified exponentially weighted moving average (EWMA) scheme is one of the quality control charts such that this control chart can quickly detect a small shift. The average run length (ARL) is frequently used for the performance evaluation on control charts. This paper proposes the explicit formula for evaluating the average run length on a two-sided modified exponentially weighted moving average chart under the observations of a first-order autoregressive process, referred to as AR(1) process, with an exponential white noise. The performance comparison of the explicit formula and the numerical integral technique is carried out using the absolute relative change for checking the correct formula and the CPU time for testing speed of calculation. The results show that the ARL of the explicit formula and the numerical integral equation method are hardly different, but this explicit formula is much faster for calculating the ARL and offered accurate values. Furthermore, the cumulative sum, the classical EWMA and the modified EWMA control charts are compared and the results show that the latter is better for small and intermediate shift sizes. In addition, the explicit formula is successfully applied to real-world data in the health field as COVID-19 data in Thailand and Singapore.

Keywords: Explicit formula; average run length; modified EWMA chart; AR(1) process; exponential white noise

Statistical analysis is important for confirming consistency and has received interest from many business areas requiring increased reliability. In the manufacturing industry, statistical process control is used extensively and a control chart is one of the quality control tools and has been applied in many fields such as finance [1], health [2] and medicine [3]. In 1924, Shewhart created the first control chart which can detect a large-sized process shift quickly [4]. Next, the exponentially weighted moving average (EWMA) chart [5] and the cumulative sum (CUSUM) chart [6] were developed and found to be faster for small shift detection. In addition, other new control charts have been developed, one of which is the modified EWMA control chart. Patel et al. [7] expanded the modified EWMA control chart from a fusion of the characteristics of the Shewhart and EWMA control charts that could detect a small size shift quickly and was more effective for autocorrelated data. The modified EWMA statistic is based on the classical EWMA statistic by using past observations with additional consideration of changes in the recent past for pairs of observations in the process. Next, Khan et al. [8] increased the performance of the modified EWMA scheme by maintaining a constant r in the last term of the modified EWMA statistic.

The average run length (ARL) [9] is the average number of in-control observations before an out-of-control signal occurs and is classified based on two stages: ARL at the initial mean (

There are many examples in the literature of using the explicit formula and the NIE method for the ARL on control charts. First, Suriyakat et al. [13] presented an explicit formula and a numerical method to solve the ARL on an EWMA control chart for a first-order autoregressive (AR(1)) process with an exponential white noise. Meanwhile, Busaba et al. [14] proposed numerical approximations of ARL on a CUSUM chart for an AR(1) model with exponential white noise. Next, Pecharat et al. [15] derived an explicit formula and a numerical integration scheme for the ARL on a CUSUM control chart for a moving average process of order q (MA(q)) with an exponential white noise. Later, Peerajit et al. [16] solved the NIEs for the ARL for a long memory process with non-seasonal and seasonal autoregressive fractionally integrated moving average (ARFIMA) models on a CUSUM control chart. After that, Sukparungsee et al. [17] analyzed explicit formulas of the ARL for an EWMA control chart using an autoregressive model. Moreover, Sunthornwat et al. [18] reported an explicit formula and a numerical technique to find the ARL on an EWMA control chart for a long memory ARFIMA process, and also presented the evaluation of ARL of an EWMA control chart for a long memory ARFIMA process with optimal parameters [19]. Recently, Peerajit et al. [20] introduced the ARL evaluation for CUSUM chart on a seasonal autoregressive fractionally integrated moving average (SARFIMA) process with an exponential white noise by using explicit analytical solutions.

Autoregressive models are often used on control charts in the recent literature [21–23]. The order of an autoregressive model is the number of immediate previous values used to predict the present value. A first-order autoregressive model considered in this research is an appropriate process for numerous data sources in real life such as environmental [24], physical [25] and industrial [26] data. Moreover, the modified EWMA control chart can be effectively used with an autocorrelated data.

In this paper, we present the explicit formula to evaluate the ARL on a two-sided modified EWMA control chart for the AR(1) process with an exponential white noise, which is the error term with an exponential distribution that has been studied recently [27–29]. In the next section, the AR(1) process features are shown and applied to a modified EWMA scheme. Following this, the ARL is calculated using the explicit formula and the NIE method, and after that, the performance of the schemes to detect shifts between the CUSUM, the classical EWMA and the modified EWMA control charts with simulated and real-world data are reported and compared.

2.1 Classical and Modified EWMA Control Charts

The modified exponentially weighted moving average (EWMA) control chart introduced by Patel et al. [7] and Khan et al. [8] were adjustments of the classical EWMA scheme. Let

and the asymptotic variance of Zt is

1. If r = 0, the classical EWMA statistic coincides with

2. If r = 1, the primal modified EWMA statistic coincides with

The upper and lower control limits of the classical EWMA control chart are:

and the bound control limits of the modified EWMA control chart are:

where

The cumulative sum (CUSUM) chart has been widely used to detect small shifts similar to the EWMA chart on the control process and was initially proposed by Page [6]. Let

where q is usually called a reference value or a constant of CUSUM chart, Z0 = u is an initial value with

2.3 Modified EWMA Chart for the AR(1) Process

The equation of observations for the AR(1) process in the case of an exponential white noise is defined as:

where

The modified EWMA statistic under the upper bound assumption for the AR(1) process substituted from Eq. (5) into Eq. (1) can be arranged by recursion:

where Z0 = u is the initial value. Therefore,

The corresponding stopping time for detecting an out-of-control process on a two-sided modified EWMA control chart can be written as:

where a is the lower control limit and b is the upper control limit. If Zt is in an in-control process and substituted with the term of

The ARL of the modified EWMA control chart with the AR(1) model is given by:

where

3 Integral Equation Method for Solving ARL

For analytical solutions, the ARL on the modified EWMA control chart with the AR(1) model is developed under the condition of a unique integral equation. L(u) is defined for an initial ARL and

If

Since

From Eq. (11), the existence and uniqueness of the solutions for the integral equation are proved by the mathematical theory. The integral equation for solving the ARL on the modified EWMA chart with the AR(1) process is proved that can be existed and has a unique solution by using Banach’s fixed point theory [31].

Theorem 1: Let X be a complete metric space

Theorem 2: Let X be a complete metric space

Proof: For a first part, let

Thus, L is called a fixed point of

Next part has to show that this fixed point is unique. Given

Hence,

The explicit analytical solutions of the ARL on the modified EWMA control chart with the AR(1) model constructed after checking for unique solutions are:

Proof: In the first step, the solution of Eq. (11) as:

Consider D and take turns L(k) with Eq. (14), then

Finally, by substituting constant D from Eq. (15) into Eq. (14), then L(u) can be found:

Therefore, the solution to Eq. (13) is obtained.

For an in-control process, the exponential parameter is set to

On the other hand, the exponential parameter for an out-of-control process is defined as

5 Numerical Method for Solving the Integral Equation

The NIE method is used to solve the ARL for the AR(1) process of the two-sided modified EWMA control chart in Eq. (10). The ARL solution or LNIE(u) is approximated with the m linear equation systems over the interval [a, b] by using the composite midpoint quadrature rule [32]. This NIE method is proposed for the two-sided modified EWMA control chart by using the length of m equal divided intervals

6 Comparison of the ARL Results

In this section, the performances of the explicit formula and the NIE method are compared by using the ARL solutions such that the NIE method determines the number of division points m = 1,000.

Figure 1: The summarized processing diagram

Step 1: Specify

Step 2: Determine the initial values of the process mean on an exponential distribution as:

Step 3: Compute b when a is known by using Eq. (13) for the explicit formula or Eq. (18) for the NIE method.

Step 4: Compute

The efficiency comparison of the ARL between the explicit formula and the NIE method is measured using the absolute relative change (ARC) [33] which can be calculated as:

In addition, the speed test results are computed by the CPU time (PC System: Windows 10 Education, i7-6500U CPU@2.50 GHz Processor, 8.00 GB RAM, 64-bit Operating System) in seconds.

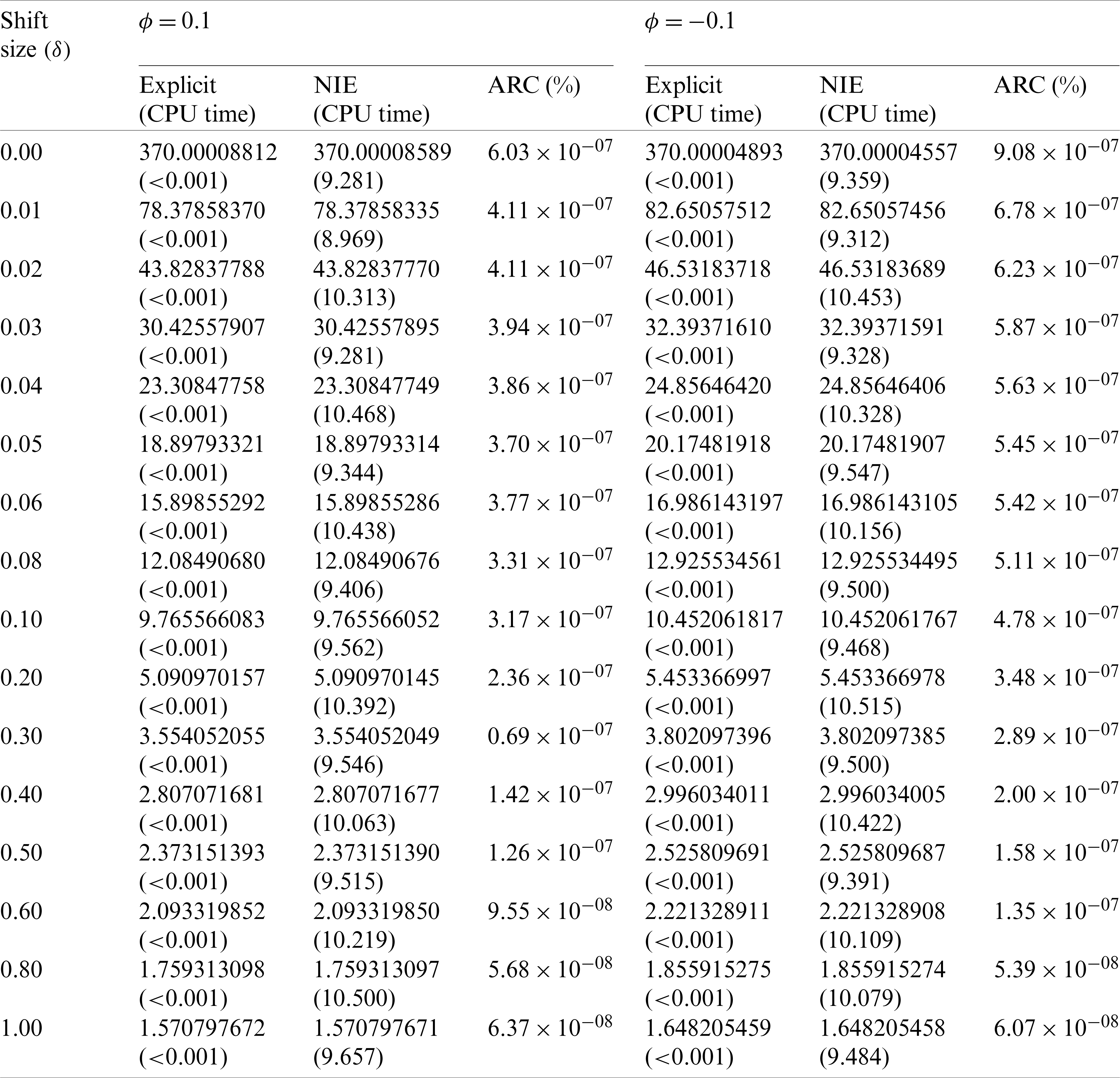

The performance comparison of the explicit formula and the NIE method is explained with the ARL, the ARC and the CPU time (Tab. 1). The first results indicate that the ARL values of the explicit formula are similar to those of the NIE method according to the ARC criterion such that ARC solutions are very low and converge to 0. For the CPU time for calculating the ARL, the explicit formula is faster than the NIE method by around 9 s.

Table 1: Comparison of ARL values on the modified EWMA control chart with the AR(1) model using explicit formulas against the NIE method given

The performance of the modified EWMA control chart on varying scales of constant r, different bound control limits [a, b] and various

where

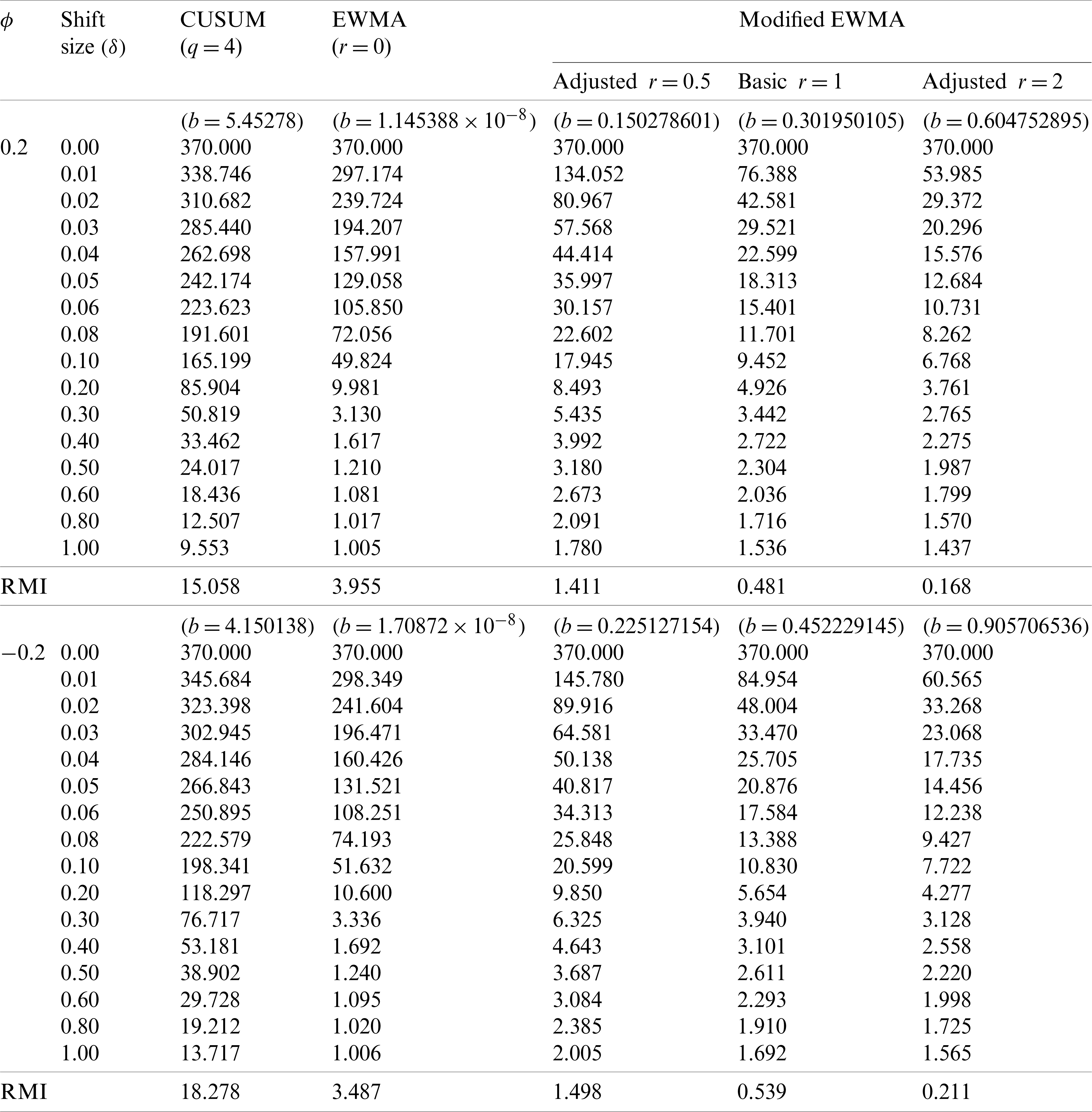

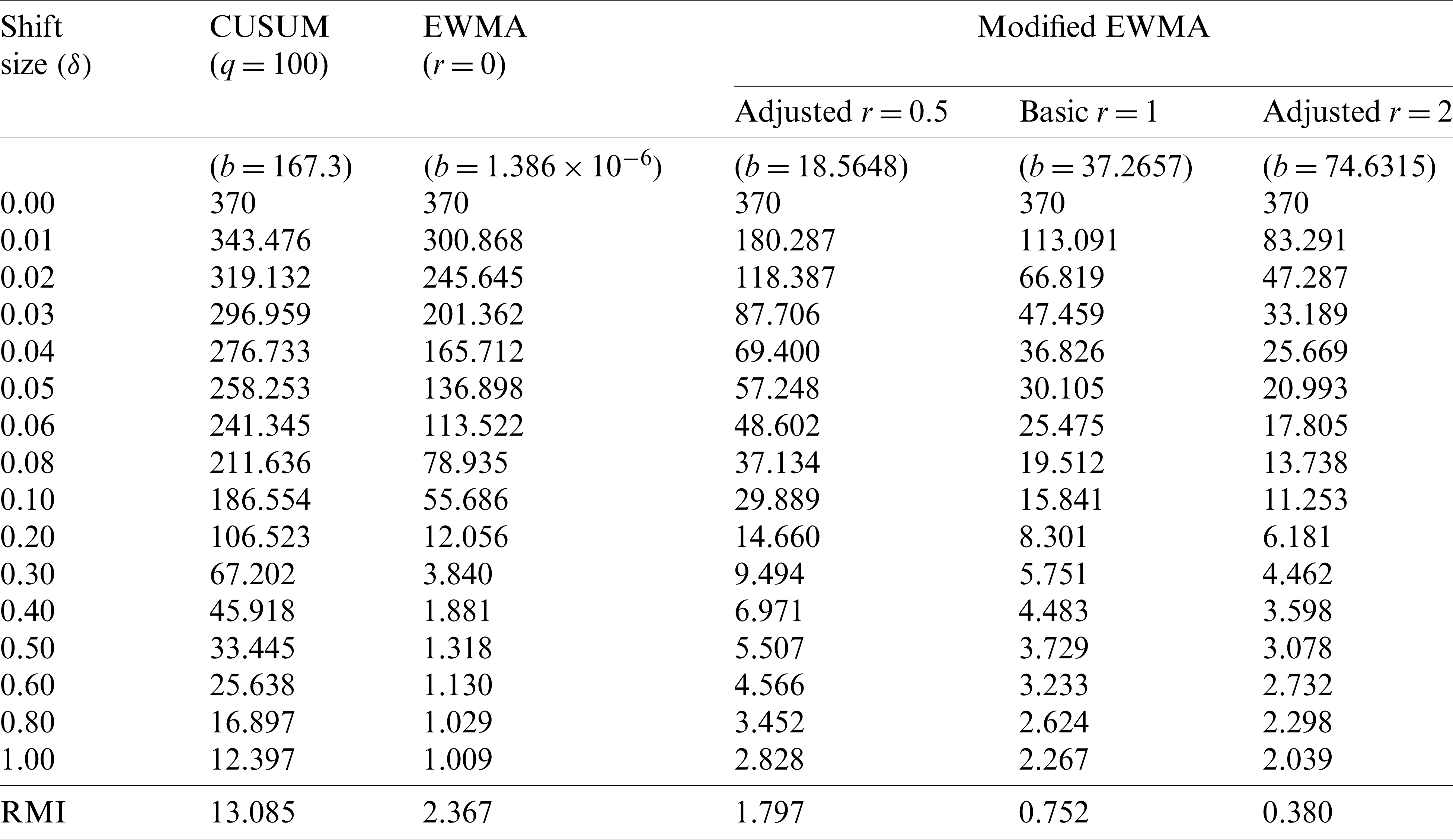

The CUSUM, the classical EWMA (r = 0), the classical modified EWMA (r = 1) and the modified EWMA control charts with adjusted r = 0.5 and r = 2 measured a capability by using the ARL and the RMI at

Table 2: Comparison of the ARL values between the CUSUM, the classical EWMA and modified EWMA control charts given

Figure 2: Plot of the CUSUM, the classical EWMA and modified EWMA control charts given (a)

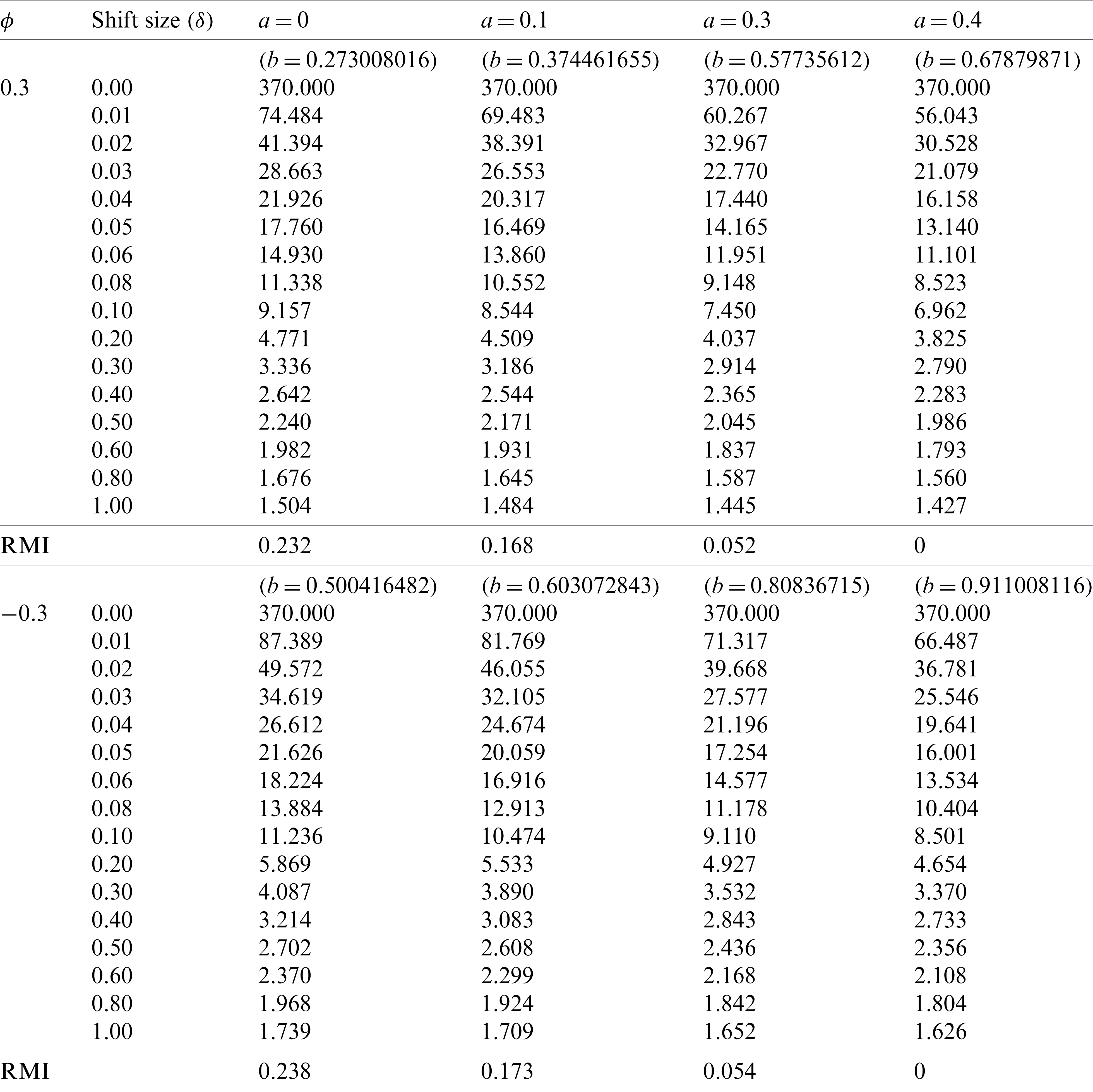

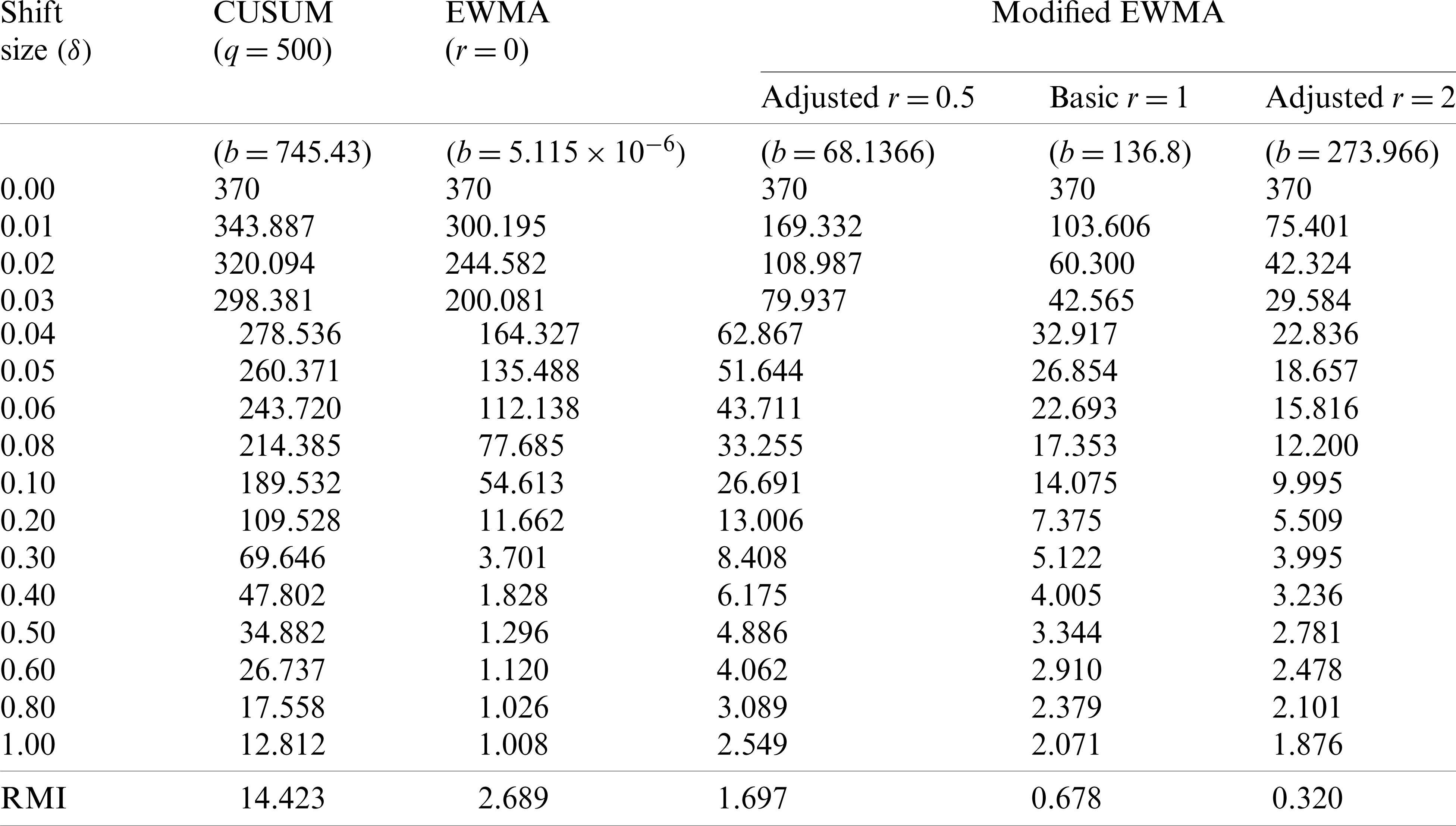

For Tab. 3, the ARL results with

Table 3: Comparison of the ARL values on the modified EWMA control chart with difference control bounds given

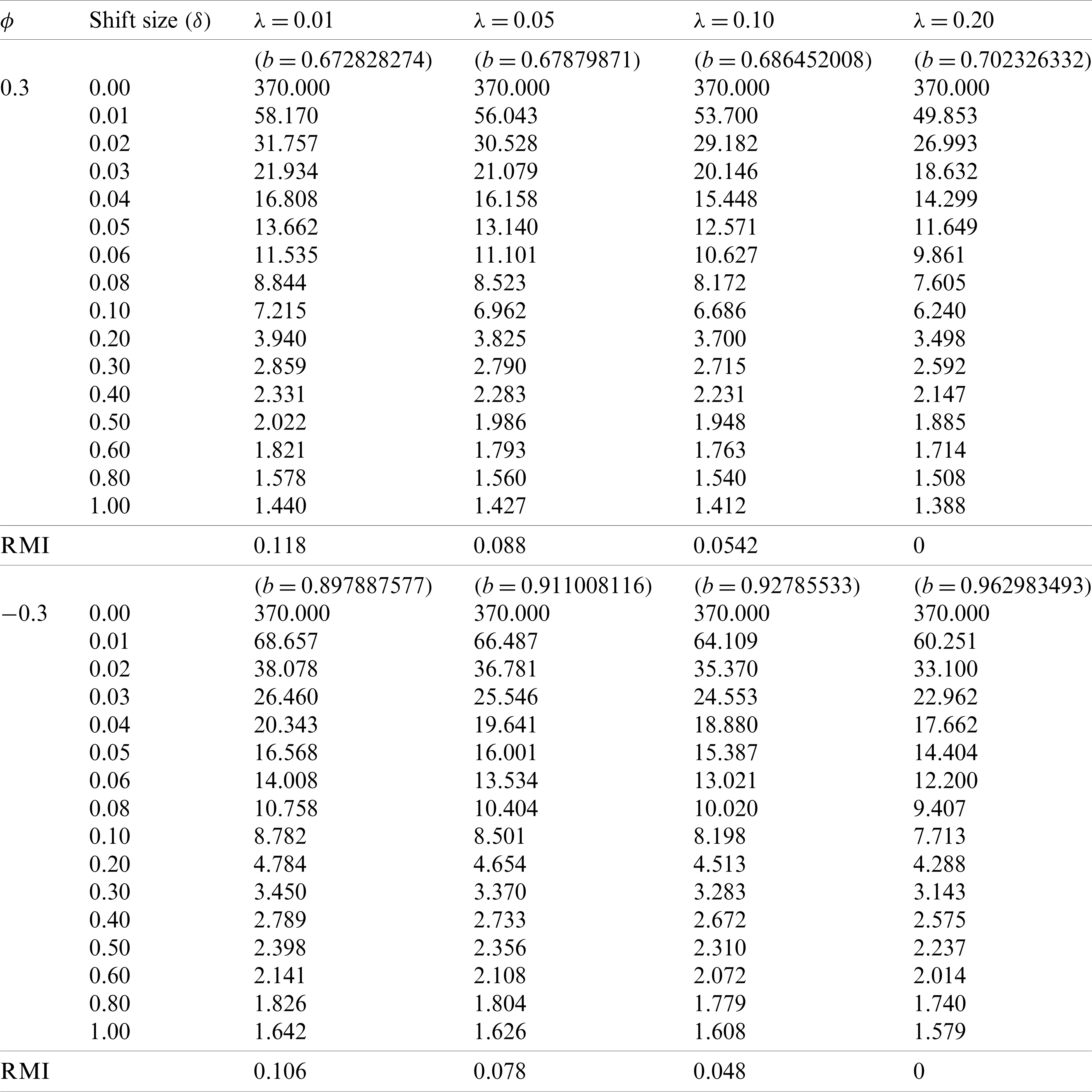

Moreover, the modified EWMA control chart is compared for various

Table 4: Comparison of the ARL values on the modified EWMA control chart with various

As an example, the modified EWMA control chart is applied to COVID-19 data in Thailand and Singapore [35,36] such that the 100 days of newly infected cases are studied when the more summation of 100 cases. These data are checked to a suitable AR(1) process with an exponential white noise at parameters of COVID-19 data in Thailand

Figure 3: Plot of the noise residual of COVID-19 data in Thailand

Figure 4: Plot of the noise residual of COVID-19 data in Singapore

From Tabs. 5 and 6, the results of ARL and the RMI are used to compare the CUSUM, the classical EWMA and modified EWMA control charts with real-world data of COVID-19 data in Thailand and Singapore. The results are in accordance with the simulation data in Tab. 2 and show that the modified EWMA control chart adjusted for high r performs well for small and intermediate level shifts.

Table 5: Comparison of ARL values between the CUSUM, the classical EWMA and modified EWMA control charts for COVID-19 data in Thailand with

Table 6: Comparison of ARL values between the CUSUM, the classical EWMA and modified EWMA control charts for COVID-19 data in Singapore with

In Fig. 5, the modified EWMA control chart with r = 2 and the classical EWMA control chart are plotted by calculating Zt of COVID-19 data in Thailand and Singapore at the exponential smoothing parameter

Figure 5: Plot of the classical EWMA and modified EWMA control chart with r = 2 for COVID-19 data in (a) Thailand and (b) Singapore

The performance of a control chart can be evaluated by using the ARL. In this paper, the explicit formula and the numerical integral equation (NIE) method of ARL solutions are established on a two-sided modified EWMA control chart for an AR(1) process with an exponential white noise. The ARL results of both methods are computed and their performances compared via the ARC and the CPU time. The explicit formula shows the actual values of the ARL and is faster calculation than the NIE approach. Moreover, the ARL and RMI results are compared between the CUSUM, the classical and modified EWMA control charts with various r, for which the latter provides better detection for small and intermediate shifts. Next, the performance of the modified EWMA control chart is tested on various bound control limits and is found to be better for higher upper bound values. In addition, this model is applied to the real-world data (COVID-19 data in Thailand and Singapore), with which it obtains similar results as with the simulated data; this result supports the excellent performance of the modified EWMA control chart. In future research, we will establish the optimal bound control limits of the modified EWMA control chart and hope to extend our approach to many new control charts currently under development for different processes.

Funding Statement: The research was supported by King Mongkut’s University of Technology North Bangkok Contract No. KMUTNB-62-KNOW-018.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Kovarik, M., Sarga, L., Klimek, P. (2015). Usage of control charts for time series analysis in financial management. Journal of Business Economics and Management, 16(1), 138–158. DOI 10.3846/16111699.2012.732106. [Google Scholar] [CrossRef]

2. Ozilgen, S. (2011). Statistical quality control charts: New tools for studying the body mass index of populations from the young to the elderly. Journal of Nutrition, Health & Aging, 15(5), 333–334. DOI 10.1007/s12603-010-0290-8. [Google Scholar] [CrossRef]

3. Poovarasan, R., Keerthi, S., Yuvashree, K., Thirumalai, C. (2018). Analysis on diabetes patients using Pearson, cost optimization, control chart. Proceedings of the International Conference on Trends in Electronics and Informatics, vol. 1, pp. 1139–1142. DOI 10.1109/ICOEI.2017.8300891. [Google Scholar] [CrossRef]

4. Montgomery, D. C. (2013). Introduction to statistical quality control. New Jersey: John Wiley & Sons. [Google Scholar]

5. Roberts, W. S. (1959). Control chart tests based on geometric moving averages. Technometrics, 1(3), 239–250. DOI 10.1080/00401706.1959.10489860. [Google Scholar] [CrossRef]

6. Page, E. S. (1954). Continuous inspection schemes. Biometrika, 41(1–2), 100–115. DOI 10.1093/biomet/41.1-2.100. [Google Scholar] [CrossRef]

7. Patel, A. K., Divecha, J. (2011). Modified exponentially weighted moving average (EWMA) control chart for an analytical process data. Journal of Chemical Engineering and Materials Science, 2, 12–20. DOI 10.1088/1742-6596/979/1/012097. [Google Scholar] [CrossRef]

8. Khan, N., Aslam, M., Jun, C. H. (2017). Design of a control chart using a modified EWMA statistic. Quality and Reliability Engineering International, 33(5), 1095–1104. DOI 10.1002/qre.2102. [Google Scholar] [CrossRef]

9. Khusna, H., Mashuri, M., Suhartono, S., Prastyo, D. D., Ahsan, M. (2018). Multioutput least square SVR-based multivariate EWMA control chart: The performance evaluation and application. Cogent Engineering, 5(1), 1–14. DOI 10.1080/23311916.2018.1531456. [Google Scholar] [CrossRef]

10. Flury, M. I., Quaglino, M. B. (2018). Multivariate EWMA control chart with highly asymmetric gamma distributions. Quality Technology & Quantitative Management, 15(2), 230–252. DOI 10.1080/16843703.2016.1208937. [Google Scholar] [CrossRef]

11. Chananet, C., Areepong, Y., Sukparungsee, S. (2015). A markov chain approach for average run length of EWMA and CUSUM control chart based on ZINB Model. International Journal of Applied Mathematics and Statistics, 53(1), 126–137. Available: http://www.ceser.in/ceserp/index.php/ijamas/article/view/3385. [Google Scholar]

12. Sukparungsee, S. (2012). Combining martingale and integral equation approaches for finding optimal parameters of EWMA. Applied Mathematical Sciences, 6, 4471–4482. [Google Scholar]

13. Suriyakat, W., Areepong, Y., Sukparungsee, S., Mititelu, G. (2012). On EWMA procedure for AR(1) observations with exponential white noise. International Journal of Pure and Applied Mathematics, 77, 73–83. [Google Scholar]

14. Busaba, J., Sukparungsee, S., Areepong, Y. (2012). Numerical approximations of average run length for AR(1) on exponential CUSUM. Proceedings of the International MultiConference of Engineers and Computer Scientists, vol. 2, pp. 1268–1273. [Google Scholar]

15. Petcharat, K., Sukparungsee, S., Areepong, Y. (2015). Exact solution of the average run length for the cumulative sum chart for a moving average process of order q. ScienceAsia, 41(2), 141–147. DOI 10.2306/scienceasia1513-1874.2015.41.141. [Google Scholar] [CrossRef]

16. Peerajit, W., Areepong, Y., Sukparungsee, S. (2018). Numerical integral equation method for ARL of CUSUM chart for long-memory process with non-seasonal and seasonal ARFIMA models. Thailand Statistician, 16(1), 26–37. [Google Scholar]

17. Sukparungsee, S., Areepong, Y. (2017). An explicit analytical solution of the average run length of an exponentially weighted moving average control chart using an autoregressive model. Chiang Mai Journal of Science, 44(3), 1172–1179. [Google Scholar]

18. Sunthornwat, R., Areepong, Y., Sukparungsee, S. (2017). Average run length of the long-memory autoregressive fractionally integrated moving average process of the exponential weighted moving average control chart. Cogent Mathematics, 4(1), 1–11. DOI 10.1080/23311835.2017.1358536. [Google Scholar] [CrossRef]

19. Sunthornwat, R., Areepong, Y., Sukparungsee, S. (2018). Average run length with a practical investigation of estimating parameters of the EWMA control chart on the long memory AFRIMA process. Thailand Statistician, 16(2), 190–202. [Google Scholar]

20. Peerajit, W., Areepong, Y., Sukparungsee, S. (2019). Explicit analytical solutions for ARL of CUSUM chart for a long-memory SARFIMA model. Communications in Statistics–Simulation and Computation, 48(4), 1176–1190. DOI 10.1080/03610918.2017.1408821. [Google Scholar] [CrossRef]

21. Vanhatalo, E., Kulahci, M. (2014). The effect of autocorrelation on the Hotelling T2 control chart. Quality and Reliability Engineering International, 31(8), 1779–1796. DOI 10.1002/qre.1717. [Google Scholar] [CrossRef]

22. He, Z., Wang, Z., Tsung, F., Shang, Y. (2016). A control scheme for autocorrelated bivariate binomial data. Computers and Industrial Engineering, 98, 350–359. DOI 10.1016/j.cie.2016.06.001. [Google Scholar] [CrossRef]

23. Kim, H., Lee, S. (2017). On first-order integer-valued autoregressive process with Katz family innovations. Journal of Statistical Computation and Simulation, 87(3), 546–562. DOI 10.1080/00949655.2016.1219356. [Google Scholar] [CrossRef]

24. Yadav, V., Nath, S. (2017). Forecasting of PM10 using autoregressive models and exponential smoothing technique. Asian Journal of Water, Environment and Pollution, 14(4), 109–113. DOI 10.3233/AJW-170041. [Google Scholar] [CrossRef]

25. Shapoval, A., Mouel, J. L. L., Shnirman, M., Courtillot, V. (2015). Stochastic description of the high-frequency content of daily sunspots and evidence for regime changes. Astrophysical Journal, 799(1), 1–8. DOI 10.1088/0004-637X/799/1/56. [Google Scholar] [CrossRef]

26. Hirsch, S., Hartmann, M. (2014). Persistence of firm-level profitability in the European dairy processing industry. Agricultural Economics, 45(1), 53–63. DOI 10.1111/agec.12129. [Google Scholar] [CrossRef]

27. Andel, J. (1988). On AR(1) processes with exponential white noise. Communications in Statistics–Theory and Methods, 17(5), 1481–1495. DOI 10.1080/03610928808829693. [Google Scholar] [CrossRef]

28. Fellag, H., Ibazizen, M. (2001). Estimation of the first-order autoregressive model with contaminated exponential white noise. Journal of Mathematical Sciences, 106(1), 2652–2656. DOI 10.1023/A:1011318515549. [Google Scholar] [CrossRef]

29. Pereira, I., Amaral-Turkman, M. A. (2004). Bayesian prediction in threshold autoregressive models with exponential white noise. Test, 13(1), 45–64. DOI 10.1007/BF02603000. [Google Scholar] [CrossRef]

30. Champ, C. W., Rigdon, S. E. (1991). A comparison of the Markov Chain and the integral equation approaches for evaluating the run length distribution of quality control charts. Communication in Statistics–Simulation, 20(1), 191–203. DOI 10.1080/03610919108812948. [Google Scholar] [CrossRef]

31. Davison, K. R., Donsig, A. P. (2010). Real analysis with real applications. New York: Springer-Verlag. [Google Scholar]

32. Phanthuna, P., Areepong, Y., Sukparungsee, S. (2018). Numerical integral equation methods of average run length on modified EWMA control chart for exponential AR(1) process. Proceedings of the International MultiConference of Engineers and Computer Scientists, vol. 2, pp. 845–847. [Google Scholar]

33. Nguyen, Q. T., Tran, K. P., Castagliola, P., Celano, G., Lardjane, S. (2019). One-sided synthetic control charts for monitoring the multivariate coefficient of variation. Journal of Statistical Computation and Simulation, 89(10), 1841–1862. DOI 10.1080/00949655.2019.1600694. [Google Scholar] [CrossRef]

34. Tang, A., Castagliola, P., Sun, J., Hu, X. (2018). Optimal design of the adaptive EWMA chart for the mean based on median run length and expected median run length. Quality Technology and Quantitative Management, 16(4), 439–458. DOI 10.1080/16843703.2018.1460908. [Google Scholar] [CrossRef]

35. WHO. (2020). Thailand situation reports: Coronavirus disease (COVID-19) dashboard. https://covid19.who.int/region/wpro/country/sg. [Google Scholar]

36. WHO. (2020). Singapore situation reports: Coronavirus disease (COVID-19) dashboard. https://covid19.who.int/region/searo/country/th. [Google Scholar]

37. Lucas, J. M., Saccucci, M. S. (1990). Exponentially weighted moving average control schemes: Properties and enhancements. Technometrics, 32(1), 1–12. DOI 10.1080/00401706.1990.10484583. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |