| Computer Modeling in Engineering & Sciences |  |

DOI: 10.32604/cmes.2021.014265

ARTICLE

E-Commerce Supply Chain Process Optimization Based on Whole-Process Sharing of Internet of Things Identification Technology

1School of Economics and Management, Tongji University, Shanghai, 200092, China

2SILC Business School, Shanghai University, Shanghai, 201800, China

*Corresponding Author: Jun Chen. Email: chenjun1@shu.edu.cn

Received: 14 September 2020; Accepted: 12 November 2020

Abstract: With in-depth development of the Internet of Things (IoT) in various industries, the informatization process of various industries has also entered the fast lane. This article aims to solve the supply chain process problem in e-commerce, focusing on the specific application of Internet of Things technology in e-commerce. Warehousing logistics is an important link in today’s e-commerce transactions. This article proposes a distributed analysis method for RFID-based e-commerce warehousing process optimization and an e-commerce supply chain management process based on Internet of Things technology. This article first introduces the advantages and disadvantages of shared IoT identification technology and the IoT resource sharing platform based on the three-layer abstract data model and representational state transfer (REST) style. Combining actual IoT applications and the characteristics of an existing platform, a REST-based IoT resource sharing platform is proposed. Combined with actual projects, a REST-based IoT resource sharing platform was built, and key technology experiments were conducted for verification. Finally, optimizing the e-commerce supply chain management process under Internet of Things technology and explaining the advantages of optimized e-commerce supply chain management are discussed. Research on this subject provides a theoretical basis for the application of the Internet of Things in e-commerce and has practical significance and practical value for managing service capabilities and service levels in e-commerce.

Keywords: Shared IoT identification technology; e-commerce; supply chain process; optimization

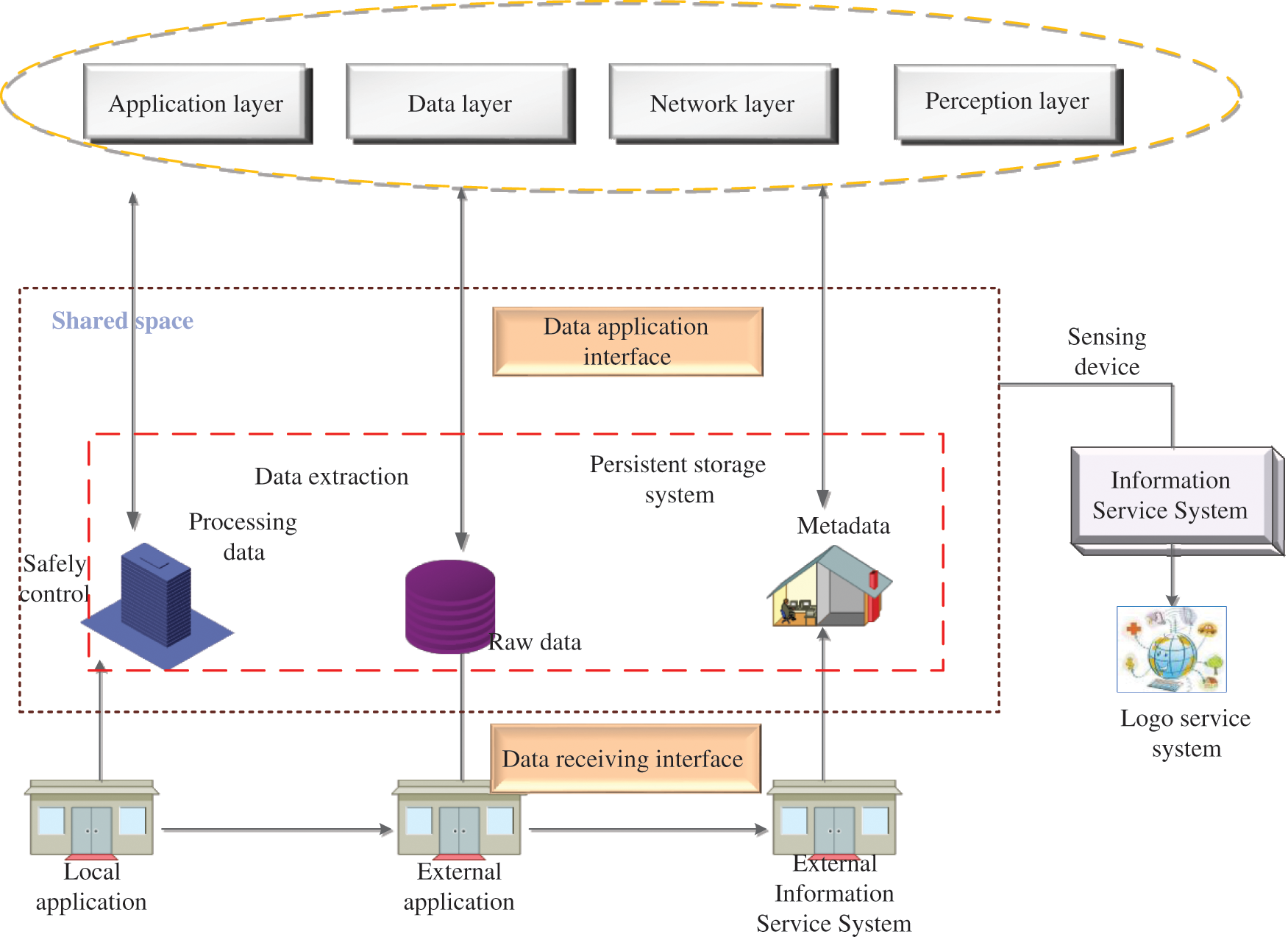

Although the Internet of Things has reached a given scale of applications in logistics, transportation, power and other industries, it remains in the early stages of development, and its informatization and intelligence are still low [1]. Thus, research is required to break through the informatization and intelligence of the Internet of Things. From the perspective of information processing, as shown on the left side of Fig. 1, the Internet of Things can be divided into four layers from bottom to top: perception, network, data and application [2]. The information service system is located in the data layer, receives massive multisource heterogeneous data downwards, serves various scale applications upwards, provides diversified information services, plays the role of connecting the previous and the next, and is the prerequisite for the interconnection of the Internet of Things [3]. The information service system can enable IoT applications for information sampling, intelligent tracking, intelligent monitoring and intelligent management of various objects in the real world [4]. Therefore, the IoT information service system is an indispensable cornerstone of the informatization process of the IoT. As an important means of informatization and intelligence of the Internet of Things, the Internet of Things information service system is an important research direction, and its structure is shown on the right side of Fig. 1. The IoT information service system is mainly composed of persistent storage systems, data interfaces, service operations, security mechanisms, sharing mechanisms, etc. In terms of function, the system’s goal is to store and manage IoT data, support the information processing of data of different scales (real-time and historical), provide good openness, and support the realization of data sharing between different IoT applications [5]. Based on this system, IoT applications can describe information sampling of various objects in the real world, as well as intelligent tracking, monitoring and management functions.

Figure 1: IoT hierarchy and information service system

Internet of Things data have the characteristics of multisource heterogeneity, large scale, spatiotemporal correlation, high redundancy, and multidimensional scalar [6]. The existing Internet of Things information service system solutions have achieved better results in spatiotemporal correlation processing and multidimensional event queries. There are many positive results; however, problems surrounding poor storage performance and difficulty in data sharing with massive heterogeneous data sets still exist. The problem of data storage is mainly reflected in the fact that old-fashioned relational database storage models cannot meet the requirements of multisource, heterogeneous, and massive IoT data storage [7]. The problem of data sharing is mainly reflected in the lack of an effective sharing mechanism to solve the closed-loop application of the Internet of Things, which easily forms information islands.

The key technologies involved in the three levels of the Internet of Things architecture are important guarantees for the ultimate realization and implementation of the Internet of Things. The key technologies involved in the Internet of Things include identification technology, wireless sensor networks (sensor gateways, sensors), middleware, client software, user card authentication and security, remote communication (mobile network/Internet, etc.), security and privacy and intelligent processing technology (cloud computing, etc.) [8]. This article mainly introduces shared IoT identification technology, proposes a REST-based IoT resource sharing platform model, and conducts key technology experimental verification. Finally, optimizing the e-commerce supply chain management process with Internet of Things technology and the advantages of optimized e-commerce supply chain management are discussed. Research on this subject provides a theoretical basis for the application of the Internet of Things in e-commerce and has practical significance and value when managing service capabilities and service levels in e-commerce.

2.1 Information Sharing Service Based on REST

REST is a design criterion that aims to guide the development of network programs, reduce development complexity, and improve system scalability.

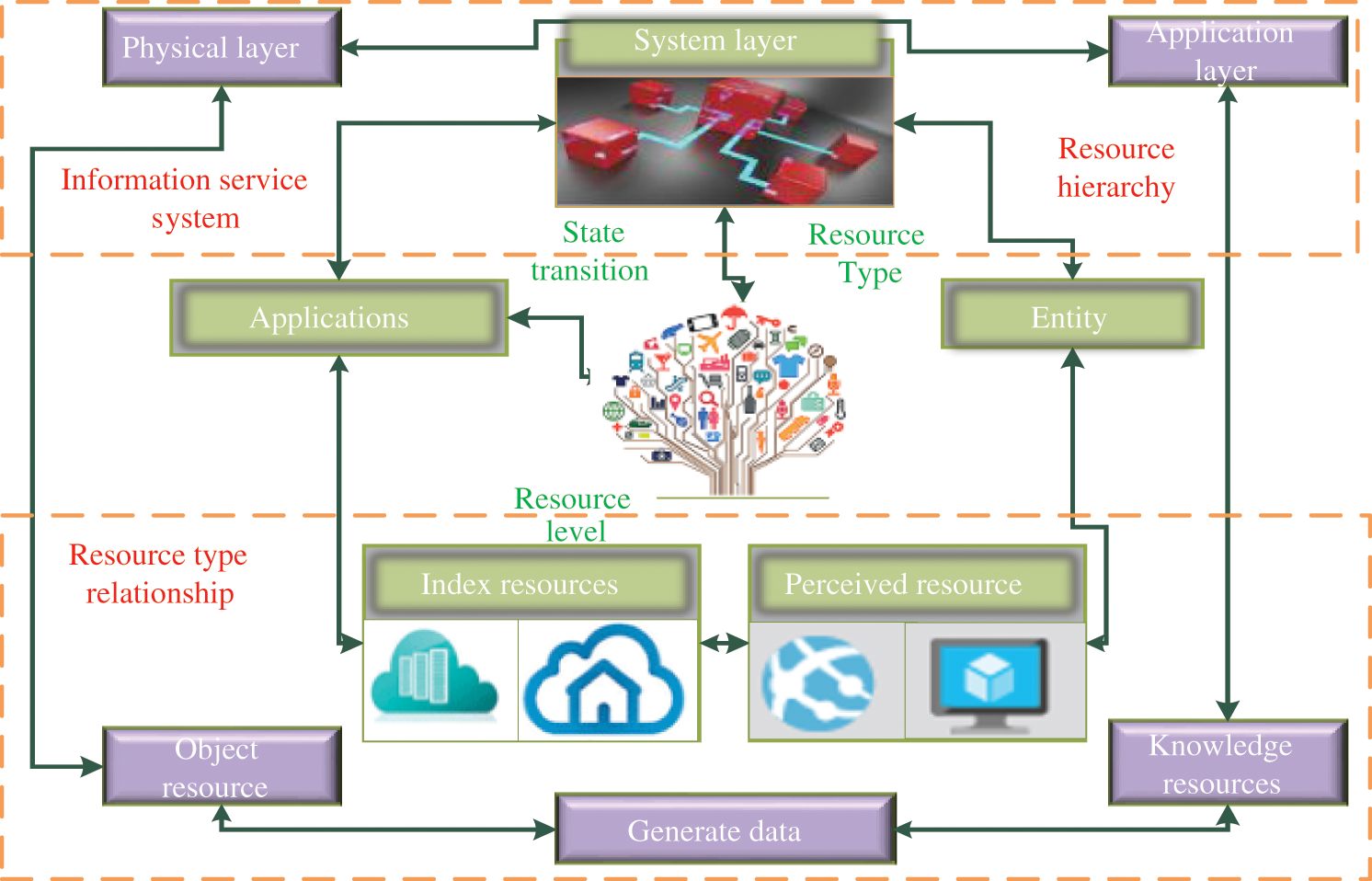

In the REST design principle, all entities that can be called can be abstracted as resources. Resources include not only information, links, computing, storage, etc., in traditional networks but also access gateways, sensing networks, and sensing data in the Internet of Things [9]. The Internet of Things information service system designed in this paper divides resources into three categories: object resources, index resources and knowledge resources. An object resource refer to a resource corresponding to a single object, which is a single data record or a collection of data records. An index resource refers to an index of a certain type or collection of resources, through which a resource list can be obtained, which leads to the object resource. A knowledge resource refers to a resource that is generated by operations based on object resources through certain algorithms (including statistics, filtering, image recognition, etc.) and usually represents a certain kind of knowledge [10]. To facilitate resource management, this paper carries out hierarchical management of resources, which is divided into the entity level, the application level and the system level. The entity level refers to resources that are all single entity resources, and object, index, and knowledge resources all belong to entity level resources. The application level refers to a collection of several entity resources, and there are multiple perception objects in an application. All object resources belonging to an application are grouped into the same set. Last, the system level refers to resources of the information service system level, and the information service system level is composed of several applications.

Fig. 2 shows the relationship between resource levels and resource types. The relationship between resources yields object resources and knowledge resources through state transfer by identifying index resources. Object resource identification can obtain perceptual data or knowledge resources through the state. Knowledge resources can be extracted through certain methods to obtain generated data. Fig. 2 outlines the relationship between resource types, and various resources can also have more levels of transfer paths. For example, an index resource can be transferred to another index resource to realize flexible organization of different types of resources [11].

Figure 2: Relationship between resource hierarchy and resource type

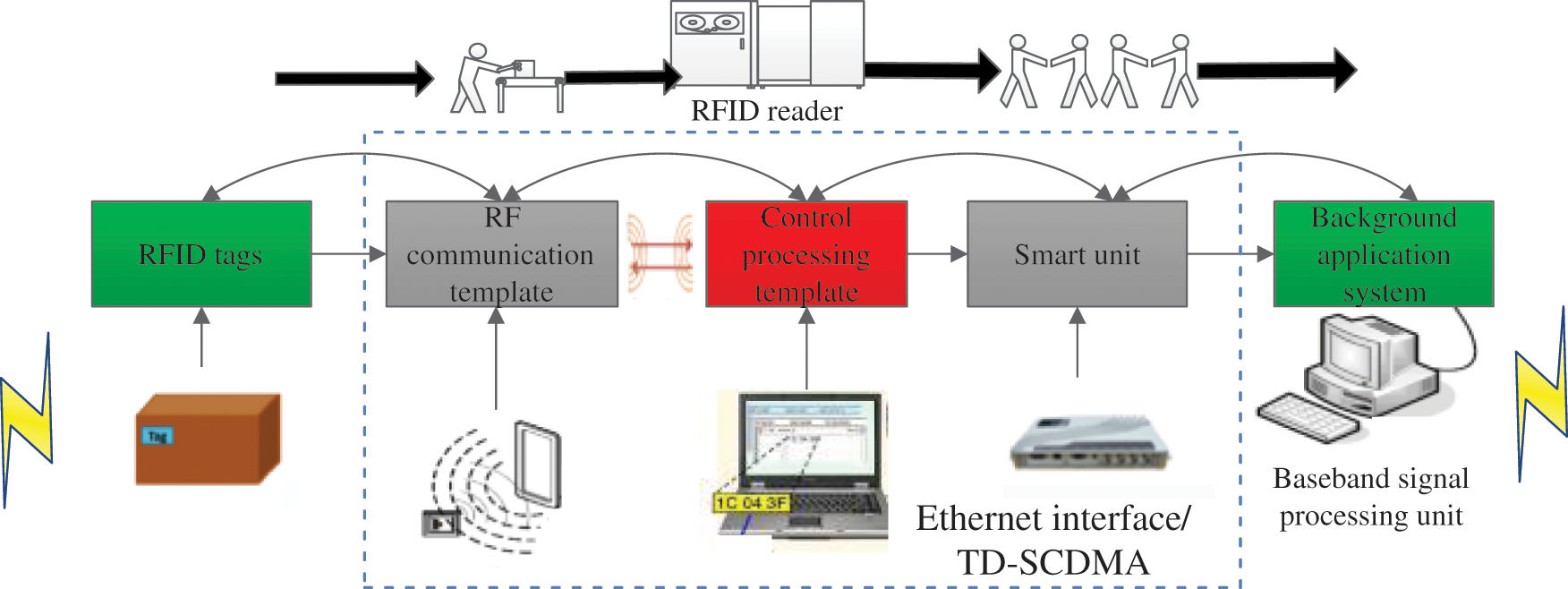

2.1.2 Identification Technology RFID

Putting electronic labels on objects to achieve efficient and flexible management is the most critical aspect of Internet of Things technology. A typical radio frequency identification technology (RFID) system consists of electronic tags, readers and information processing systems, as shown in Fig. 3. To describe the interconnection between any objects via RFID, each object must be given an identification code for identity verification. Every device that appears on this network has to obtain a unique code to identify its uniqueness, and a single item can have multiple identification numbers; each component of a composite object can have an identification number and belongs to one category [12]. Items must have a special identification ID that identifies its type, and a single item must also have an ID that is different from other items of the same kind. In addition, for certain items, their security and privacy requirements should be considered. Thus, the design of the identification structure, identification mapping mechanism, and anonymous identification technology are important research topics that promote the development of RFID technology. When investigating these topics, we recommend using the existing item identification system as much as possible with future work investigating the evolution of RFID identification and the impact on the ID network to better promote the development of the Internet of Things.

Figure 3: RFID system

The application of RFID technology in the management of income, expenditure and storage is mainly embodied in two advantages. First, a shortened operation process allows tags to be placed on pallets and packaging boxes, and readers to be placed at the entrance and exit of a distribution center so that forklifts can transport goods into and out of a warehouse quickly while capturing important data. The reader can then dynamically identify multiple tags at a time from a long distance [12]. The computer records the corresponding data based on the recorded information, which reduces required data storage. Second, the quality of inventory operations can be improved. The use of RFID technology will greatly reduce errors such as omissions in traditional inventory operations and enhance the accuracy and reliability of information. The application of RFID technology in logistics operations is mainly reflected in two aspects: logistics tracking and reducing operating costs. The RFID system uses the electronic product code (EFB) to realize logistics tracking of goods in the entire supply chain and the automatic management of the supply chain to increase the transparency of supply chain management. Additionally, because RFID technology can dynamically identify multiple data concurrently and has a large identification distance during warehousing, acceptance and warehousing are completed concurrently, allowing goods to be inspected, and warehousing and picking to occur directly after receiving the goods [13]. After the goods are inspected, they will be shipped out, which greatly reduces the number of times the goods are moved in the distribution center and reduces equipment and labor costs caused by transportation.

2.2 Route Design of E-Commerce Logistics System Based on RFID Technology

In the distribution operation module of the e-commerce logistics system, the enterprise needs to establish a transportation optimization model in the database. The model generally takes the minimum transportation cost as the optimization goal, and the factors considered are mainly related to transportation routes and transportation volumes. The e-commerce logistics system uses RFID technology to obtain real-time vehicle location information through RFID technology receivers. Additionally, the system uses RFID technology to display the vehicle location information on an electronic map and indicate the trajectory of the vehicle to obtain transportation route information. Transportation volume information can be obtained through RFID technology. The fixed arrangement of RFID readers is scattered in a given area, readers are directly connected to the data management information system, and the signal transmitter is installed on the moving vehicle [14]. When the vehicle passes by the reader, the reader will automatically scan the information on the label and enter the data information into the data management information system for storage, analysis, and processing to obtain transportation volume information. After the system collects transportation route and volume information through GPS, GIS and RFID technologies, it inputs the data into the path optimization algorithm library to calculate the optimal path. The optimal path model is:

where, yij represents the distance or transportation unit price from warehouse or distribution center i to demand point j, xij represents the transportation volume from warehouse or distribution center i to demand point j,  represents the supply volume of warehouse or distribution center i, and

represents the supply volume of warehouse or distribution center i, and  represents demand at point j.

represents demand at point j.

3 E-Commerce Supply Chain Process Optimization Based on Shared IoT Identification Technology

3.1 Supply Chain Management Mode in an E-Commerce Environment

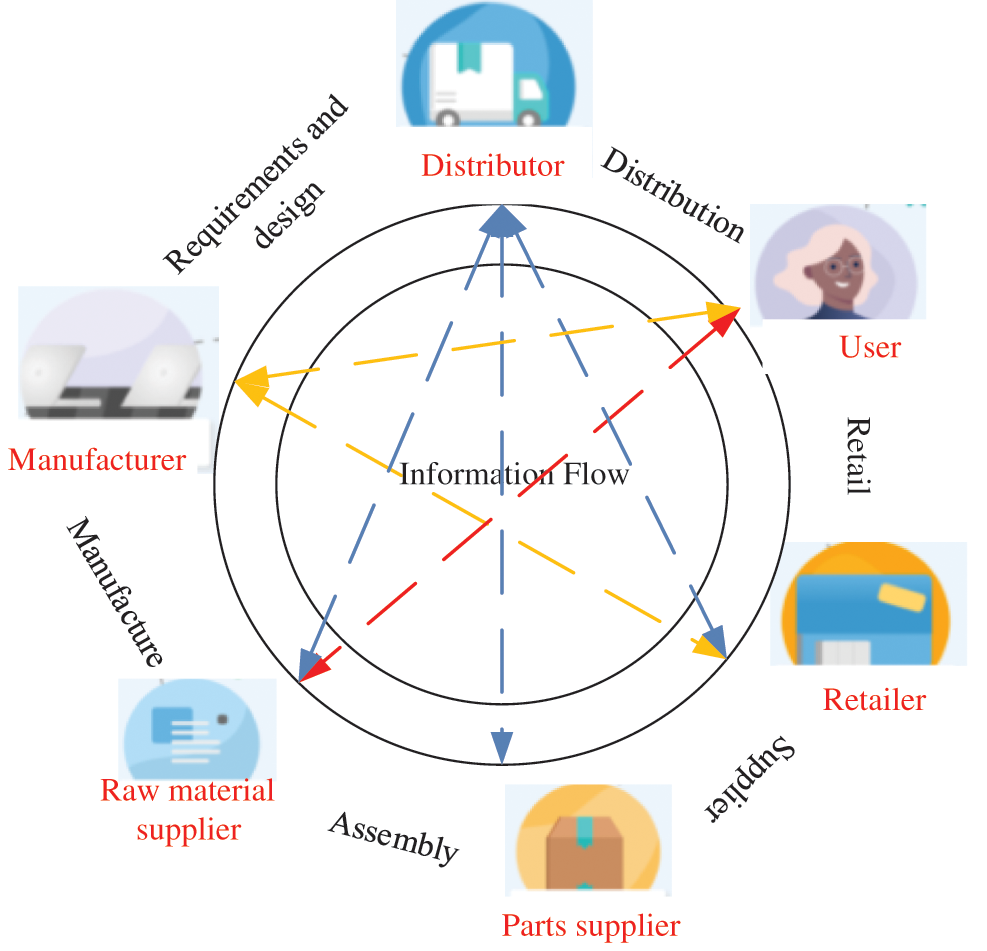

Information flow management, capital flow management and logistics management constitute the three major parts of supply chain management. With the widespread application of e-commerce, information and funds can be transmitted transparently, quickly and accurately between the member nodes of the supply chain through the Internet, greatly improving the management of information flow and capital flow in supply chain management. Breaking through and changing the traditional scope of raw material procurement, production, sales and service is an inevitable requirement of the supply chain management model in the e-commerce environment [13]. Companies in the supply chain no longer do their own things, and various internal and node companies in the supply chain should be considered. Business dealings are considered to be an overall functional process. Through effective and transparent coordination of information flow, capital flow, and logistics in the supply chain, the internal supply chain of the enterprise and the external supply chain of the enterprise can organically integrate and manage to form an integrated supply chain management system that adapts to the new requirements of high quality, high flexibility and low cost put forward by the market on enterprise production management under the new competitive environment.

Because the core enterprises of e-commerce and upstream suppliers, downstream end customers, banks, and logistics centers realize rapid information exchange through the Internet, and at the same time information exchange can also be carried out between enterprises at various nodes in the supply chain. Through the application of e-commerce, the traditional model has been completely disrupted, and the islands of various business nodes in the supply chain have been effectively connected to achieve true business information integration and sharing. In the transaction link, e-commerce needs to further improve the logistics management link, minimize the time required for logistics in the supply chain, and achieve unified synchronization of logistics management with information flow and capital flow management, thereby establishing a truly powerful and fast-responsive supply chain management system.

The supply chain management model diagram in the e-commerce environment is shown in Fig. 4.

Figure 4: Supply chain management model diagram in an e-commerce environment

3.2 Case Analysis of Supply Chain Management Optimization for E-Commerce Manufacturers Based on Internet of Things Technology

This section uses a specific example to explain how to optimize the supply chain management of e-commerce under the Internet of Things technology. D is a third-party logistics company that has been responsible for the storage and distribution of raw materials, ready-made garments for company A, and an e-commerce garment manufacturer. D has its own self-built logistics fleet, a GPS/GIS positioning system is installed on each truck, and D also has its own warehouse. B is a long-term customer of A, and C is a key raw material supplier for A to manufacture garments. To reduce the bullwhip effect, A and customer B, raw material supplier C, and third-party logistics D have realized four-party production and marketing data information sharing. A places a raw material order to C, and RFID chips are embedded in each raw material package. When the materials arrive at the port, they are stored in the temporary customs warehouse. The customs and port also use RFID technology; thus, customs clearance can be automated, reducing customs clearance time. A and D can also stay informed based on the RFID information embedded in the materials by understanding their specific location and state [15]. Based on A’s request, D will transport part of the materials to its own warehouse for storage and part of the materials to A’s production base. The storage of the materials is also based on RFID technology; thus, the item information is automatically included in the information system, achieving precise positioning. Packaging processing, inventory, and outbound picking in the warehouse are equally efficient and error-free. RFID chips are also embedded in the packaging of A’s garment products. The movement of garments is similar to D’s raw materials. When the number of shelves in D’s warehouse drops below the safety stock, the system will automatically send replenishment requests to A and C. C can monitor its own raw material quantity reserves at any time to replenish inventory at any time. When A transports garments to B via an expressway, real-time monitoring of the location of the goods can be realized through the RFID readers installed along the expressway and the GPS installed on the vehicle, which can prevent the loss of items, package dropping and misdelivery. Similarly, A can also monitor the sales of ready-to-wear garments in real time through the RFID reader installed in the warehouse of distributor B to make the most timely and accurate raw material purchase, production, and replenishment for the market.

Based on the Internet of Things, the entire e-commerce supply chain is defined by transparency. Enterprises can realize real-time monitoring of each product and manage the logistics system. Companies can monitor and share information on the circulation of products in the supply chain and can analyze and predict the information that products will generate at each stage of the supply chain. Through the reaction of the production market at each stage, companies can estimate the probability of accidents or future trends, improving the company’s ability to speed up the company’s response speed.

3.3 Information Sharing Supply Chain Management Based on the Internet of Things Identity Management Public Service Platform (NIOT)

The Internet of Things has many resources, and describing resource discovery and positioning can be difficult. This article uses the NIOT Internet of Things logo platform to carry out unified logo management on large resources.

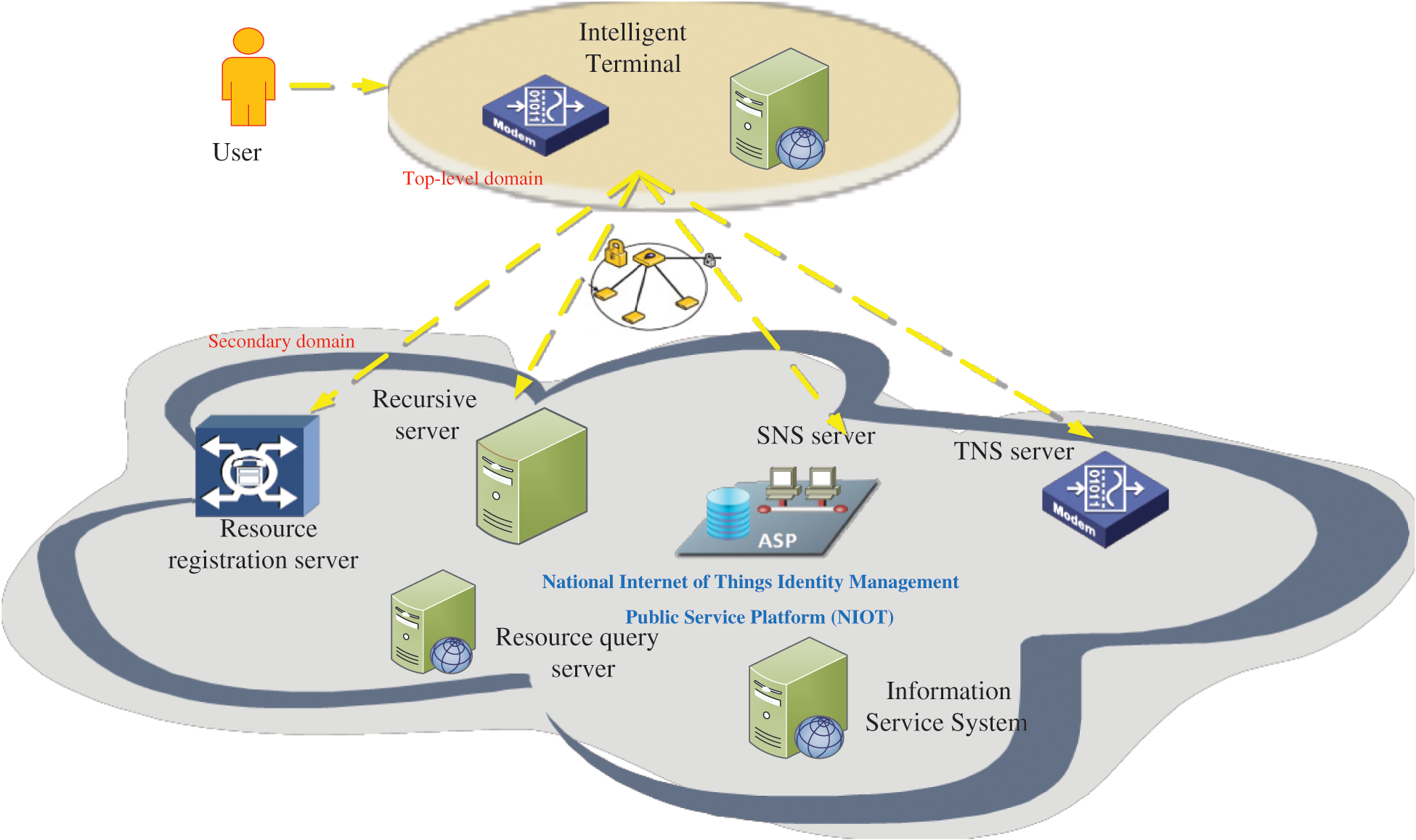

3.3.1 Resource Discovery and Positioning

The key to achieving interconnection among applications is resource discovery and location that determines the location of data [16]. Discovery refers to searching for all resources of a single object throughout its entire life cycle. Multiple links may establish independent information service systems (such as the production, logistics, and sales links of the product life cycle), so the discovery involves different information service systems. Positioning determines the address of the information service system of a single resource, which is realized by analyzing the service. This article uses NIOT to manage resource identification to facilitate resource discovery and location. The NIOT platform provides public services for Internet of Things resources based on DNS, including three subsystems: resource registration, analysis and search. The relationship between its system architecture and information service system is shown in Fig. 5. For heterogeneous identification in the Internet of Things, NIOT is compatible with heterogeneous multi-encoding when designing a two-stage identification structure, standard code, item code, standard code identification coding format, and item code identification entity objects by the standard code name server SNS and item code name server TNS provides services [17].

Figure 5: Information service system and Internet of Things logo management public service platform

3.3.2 REST Model Data Transmission Optimization

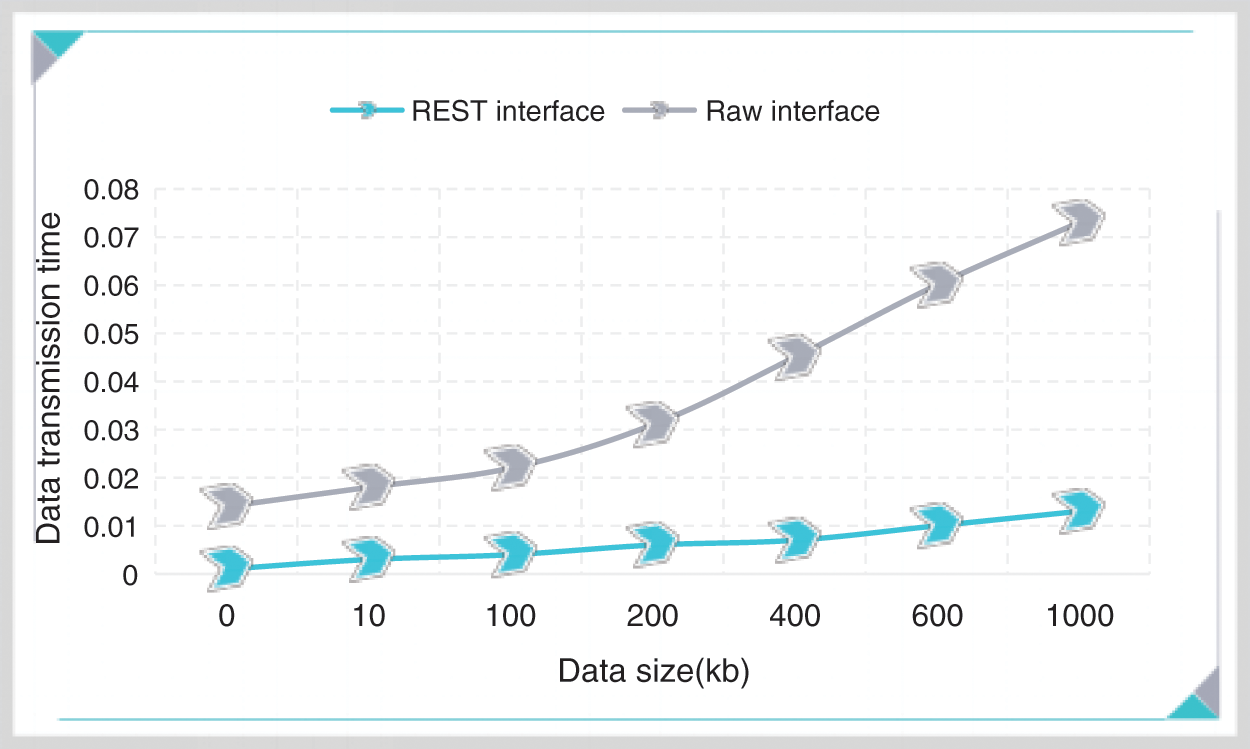

After resources are released and located, they need to interact with the outside world. Standard interfaces are used to reduce interaction costs and facilitate data sharing. Based on the REST style information service interface, the interaction can be realized by many HTTP standard requests. This article defines GET, PUT, DELETE and POST to complete CRUD (Create, Retrieve, Update, Delete) operations on resources [17]. On the other hand, REST divides the system hierarchically, which increases the overhead and delay of data processing between layers. Concurrently, the HTTP protocol packet header will also reduce system performance. This paper conducts a performance evaluation of the REST application (as shown in Fig. 6), evaluates the information service system using the REST data interface and the native data interface, and tests the data transmission delay at different data sizes. The results show that the use of the REST architecture increases the data transmission delay; however, it remains within an acceptable range.

Figure 6: Performance comparison between the REST interface and native data interface

When a resource is created in the information service system, its identifier is registered in NIOT. The registration information includes resource identification (URI), item code, standard code, descriptive information of data abstraction standards (such as domain), etc. NIOT performs URI mapping on the received resource information and completes the registration. Users can use the analysis system to locate the data location and use the search system to realize the retrieval and discovery of related resources [18].

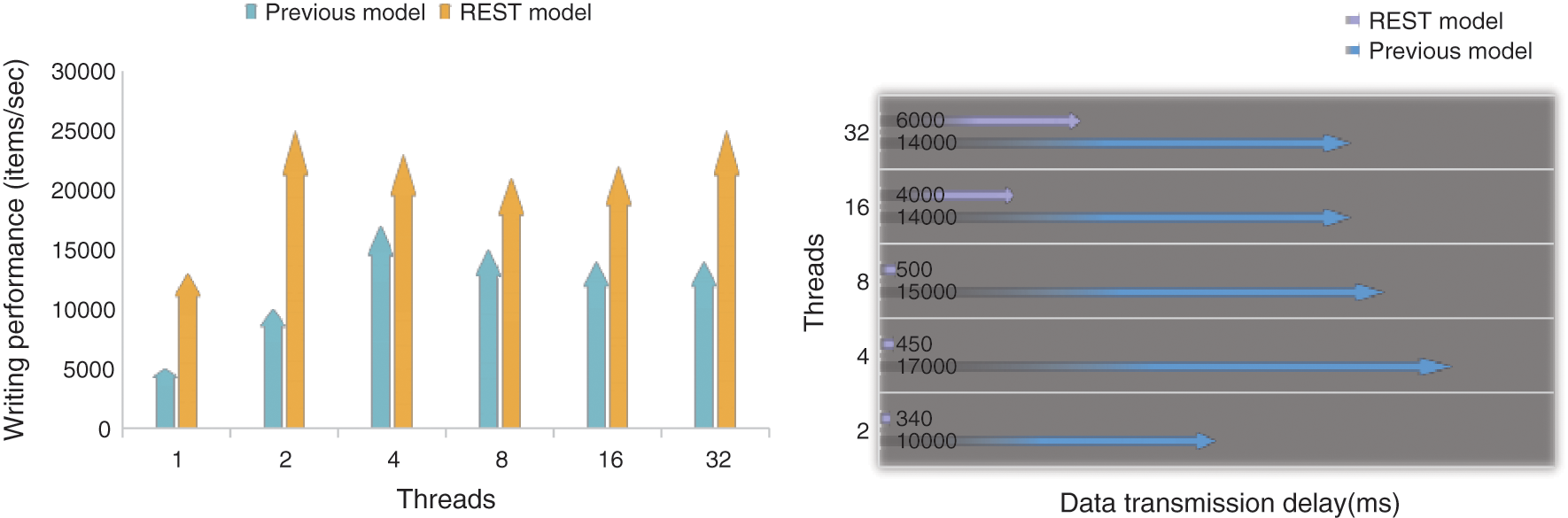

The evaluation data selected real data from the Internet of Things, including 2.3 million WSN data from the Intel Berkeley Lab [19]. The performance evaluation results are shown in Fig. 7. The test results show that the performance of the proposed scheme has been significantly improved. On the other hand, the test of the overall system is similar to that of a simple database system because the standard interface constructed by REST degrades performance; the cluster mode is used to store massive data, and fragmentation increases the data transmission delay [20].

Figure 7: Scheme performance comparison

Based on the key technologies in the Internet of Things, and combining Internet of Things identification technology and RFID technology, this article proposes a distributed analysis method for RFID-based e-commerce warehousing process optimization and an e-commerce supply chain management process based on Internet of Things technology. Optimization can help solve the problem of the e-commerce supply chain process to a certain extent. Warehousing logistics is an important link in today’s e-commerce transactions. Faced with the short-legged logistics problem that has hindered the rapid development of e-commerce, this article clarifies the current status of e-commerce items inside and outside of warehouses. Through the analysis of RFID technology in the Internet of Things, a complete set of RFID technology-based warehousing process optimization and transformation design is proposed. Based on current market conditions, warehouse hardware equipment and equipment cost estimation analysis are required to achieve warehousing process optimization and transformation. The article analyzes traditional supply chain management for these problems, optimizes the e-commerce supply chain management process with Internet of Things technology, and uses an e-commerce clothing manufacturer as an example to explain the advantages of optimized e-commerce supply chain management. The research on this topic provides a theoretical basis for the IoT-based applications in e-commerce and has practical value when solving the problem of service capabilities and service levels in e-commerce.

Funding Statement: The author(s) received no specific funding for this study.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Jin, M., Wang, H., Zhang, Q., Zeng, Y. (2020). Supply chain optimization based on chain management and mass customization. Information Systems and e-Business Management, 2(1), 647–664. DOI 10.1007/s10257-018-0389-8. [Google Scholar] [CrossRef]

2. Li, D. (2016). Perspective for smart factory in petrochemical industry. Computers & Chemical Engineering, 9(1), 136–148. DOI 10.1016/j.compchemeng.2016.03.006. [Google Scholar] [CrossRef]

3. Liu, L., Geng, K. (2016). Intelligent storage system architecture research based on the Internet of Things. International Conference on Industrial IoT Technologies and Applications, pp. 247–256. Guangzhou, China, Cham: Springer. [Google Scholar]

4. Liu, C., Feng, Y., Lin, D., Wu, L., Guo, M. (2020). (IoT based laundry services: An application of big data analytics, intelligent logistics management, and machine learning techniques. International Journal of Production Research, 58(17), 5113–5131. DOI 10.1080/00207543.2019.1677961. [Google Scholar] [CrossRef]

5. Shang, X., Zhang, R., Zhu, X., Zhou, Q. (2016). Design theory, modelling and the application for the Internet of Things service. Enterprise Information Systems, 10(3), 249–267. DOI 10.1080/17517575.2015.1075592. [Google Scholar] [CrossRef]

6. Ruan, J., Shi, Y. (2016). Monitoring and assessing fruit freshness in IoT-based e-commerce delivery using scenario analysis and interval number approaches. Information Sciences, 373(3), 557–570. DOI 10.1016/j.ins.2016.07.014. [Google Scholar] [CrossRef]

7. He, Y., Zhou, F., Qi, M., Wang, X. (2020). Joint distribution: Service paradigm, key technologies and its application in the context of Chinese express industry. International Journal of Logistics Research and Applications, 23(3), 211–227. DOI 10.1080/13675567.2019.1667314. [Google Scholar] [CrossRef]

8. Wang, J., Lim, M. K., Zhan, Y., Wang, X. (2020). An intelligent logistics service system for enhancing dispatching operations in an IoT environment. Transportation Research Part E: Logistics and Transportation Review, 13(5), 101–105. DOI 10.1016/j.tre.2020.101886. [Google Scholar] [CrossRef]

9. Li, B., Ling, Y., Tian, M., Zheng, S. (2018). Design and implementation of sugarcane growth monitoring system based on RFID and ZigBee. International Journal of Online and Biomedical Engineering, 14(3), 96–106. DOI 10.3991/ijoe.v14i03.8413. [Google Scholar] [CrossRef]

10. Zhou, Z., Pei, J., Liu, X., Fu, H., Pardalos, P. M. (2020). Effects of resource occupation and decision authority decentralisation on performance of the IoT-based virtual enterprise in central China. International Journal of Production, 2(1), 1–17. DOI 10.1080/00207543.2020.1806369. [Google Scholar] [CrossRef]

11. Zhang, J. (2017). The integration of technology and the publishing industry in China. Publishing Research Quarterly, 33(2), 173–182. DOI 10.1007/s12109-017-9504-9. [Google Scholar] [CrossRef]

12. Ping, H., Wang, J., Ma, Z., Du, Y. (2018). Mini-review of application of IoT technology in monitoring agricultural products quality and safety. International Journal of Agricultural and Biological Engineering, 11(5), 35–45. DOI 10.25165/j.ijabe.20181105.3092. [Google Scholar] [CrossRef]

13. Qi, Q., Tao, F. (2018). Digital twin and big data towards smart manufacturing and industry 4.0:360 degree comparison. IEEE Access, 6(1), 3585–3593. DOI 10.1109/ACCESS.2018.2793265. [Google Scholar] [CrossRef]

14. Wu, W., Cheung, C., Lo, S. Y., Zhong, R. Y., Huang, G. Q. (2020). An IoT-enabled real-time logistics system for a third party company: A case study. Procedia Manufacturing, 4(9), 16–23. DOI 10.1016/j.promfg.2020.06.005. [Google Scholar] [CrossRef]

15. Zheng, Z., Xie, S., Dai, H. N., Chen, X., Wang, H. (2018). Blockchain challenges and opportunities: A survey. International Journal of Web and Grid Services, 14(4), 352–375. DOI 10.1504/IJWGS.2018.095647. [Google Scholar] [CrossRef]

16. Li, Z. (2017). A data classification algorithm of internet of things based on neural network. International Journal of Online and Biomedical Engineering, 13(9), 28–37. DOI 10.3991/ijoe.v13i09.7587. [Google Scholar] [CrossRef]

17. Yang, A., Li, Y., Liu, C., Li, J., Zhang, Y. et al. (2019). Research on logistics supply chain of iron and steel enterprises based on block chain technology. Future Generation Computer Systems, 10(1), 635–645. DOI 10.1016/j.future.2019.07.008. [Google Scholar] [CrossRef]

18. Ding, Y. (2019). Brief analysis about digital twin supply chain model and application. Industrial Engineering and Innovation Management, 2(1), 14–23. DOI 10.23977/ieim.2019.21003. [Google Scholar] [CrossRef]

19. Kang, P., Chen, S., Zhao, Y., Shang, X. (2018). Investigation and analysis of demand for intelligent logistics system with light intelligent packages. Management Science and Engineering, 12(4), 39–43. DOI 10.3968/11079. [Google Scholar] [CrossRef]

20. Zhou, Q., Zhang, Z., Wang, Y. (2020). Research on safety management system optimization of B2C e-commerce intelligent logistics information system based on data cube. Journal of Intelligent & Fuzzy Systems, 38(2), 1585–1592. DOI 10.3233/JIFS-179522. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |